As mentioned in a previous post, the surface tension of the substrates to be glued or printed is an important parameter to take into account during the coating process.

Indeed, whether to print on a support or to glue a support with another, the adhesive or the printing ink must be able to spread on the said support in order to obtain an optimal adhesion. In general, the higher the surface tension the more the material will be able to be printed or glued.

To be able to compare the solutions, we will take the most used structures in the luxury packaging sector: a cardboard laminated with a printable metallized polyester.

THE CORONA

The corona works as follows :

An electrode is connected to a generator of high frequency and high AC voltage. This electrode emits an electric discharge in the form of an effluvium (blue sparks with ozone emission).

The support to be processed passes under the electrode, which modifies it physically and chemically.

THE PLASMA TREATMENT

The plasma treatment concentrates more energy on a smaller surface. It differs from the corona by the absence of a visible electrode on the treatment head. Indeed “Plasma” is a gas that contains a high concentration of ions which makes it conductive. The gas is therefore used to conduct the high voltage electrical charge and thus to obtain a surface oxidation of the support which is stronger than in the case of the corona. The stronger the agitation of the atoms, the more ion is produced and therefore the more energy is contained in a volume and the more oxidizing capacity. The gas used may be air, argon and so on.

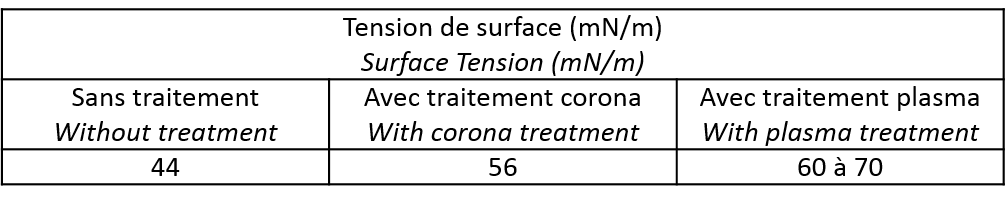

Here is a summary table giving the order of magnitude of the surface tension between without treatment and with treatment (corona or plasma) of a PET film.

The measurement of the surface tension is carried out in a conventional manner by means of test inks. These are calibrated test inks. In order to do this, a line is drawn with the ink on the support and, depending on the reaction of the ink (spreads out or droplets), the ink is selected from a higher or lower level, and so on up to the level of surface tension of the material.

A liquid may wet a support if the surface tension of the support is greater than that of the liquid.

Finally, in order to improve the adhesion of an ink or a varnish to a support, the primarization of the latter may also be an interesting option. Primerization is the application of an adhesion primer, that is to say a bonding varnish having both a good affinity with the support and the varnish / ink to be coated. In this case the affinity is chemical.

In order to obtain a good wetting of the support by a varnish or an adhesive in the case of laminating or printing, it is possible to increase the surface tension of the support by treatment or to apply a varnish for bonding between the support and The varnish to be coated via a primarization. Avoid dangerous connections, hang on!

Estelle Perrin, R&D