Be aware of your (surface) tension!

What does gluing and printing have in common? The importance of the surface tension of the substrate.

Actually, whether you need to print on a substrate, or to laminate a substrate against another, it is necessary that the adhesive or printing ink can be spread on the so-called substrate to obtain an optimal look. The best way to define the surface quality of the support is the surface tension also called superficial tension.

The surface tension or interfacial energy or surface energy, is the voltage which exists on the surface of separation of two mediums. This energy allows such insects to walk on water, a light object to remain at the surface of a liquid, the dew to remain over the flower petals …

In industry, it is essential to know the surface tension of a material. Indeed, higher the surface tension is, the better the material will be able to be printed or glued. On the contrary, the more the material has a level of low surface tension, the more it will be used as a filter (hydrophobic or oleophobic). The surface tension concept is omnipresent, particularly in the plastic, ceramic or metal industry.

For plastic: it is whether you can print or glue a particular material, whether the material has been treated for it …

For metals: measuring the surface tension is used to know if the material is clean and therefore suitable for processes of transformation

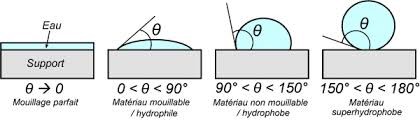

An easy example is to imagine a drop of water put on a support.

Depending on the surface tension of this medium, this drop of water will spread out with vaying degree of success:

Plus wetting angle θ is high, the less the material is wettable by water. There will therefore be an effect “droplets” if one tries to coat water on this support.

Depending on the type of varnish / glue to coat, the wetting angle is not necessarily the same.

Likewise, in the case of a corona or plasma treatment of the support, the surface tension of the substrate being increased, the wetting will be better. Conversely a substrate polluted with fingerprints … will have its surface tension decreased and therefore create a risk of bad wettability of the support with the varnish.

A method conventionally used to measure the surface tension of the substrate is the test inks method. It involves measuring the surface tension with calibrated test inks, by drawing a line of ink on the material. Depending on the reaction of the ink ( well spreads or droplets creation) we will selecting the ink of a higher or lower level, and so on until we find the level of surface tension of the material.

A liquid can wet a support if the surface tension of the substrate is greater than that of the liquid; it is why there is an interest in corona or plasma treatment that makes possible to increase the surface tension of the substrate.

In summary, to get a good wetting of the substrate by a varnish / glue in the case of a lamination or a printing, it is important to ensure that the substrate to be coated is clean and its surface tension is sufficient for receiving the varnish. In three words: watch your tension!

Estelle Perrin

R & D Project Manager