Requirements finesse of printing for markets such as luxury, food-processing and security involves a choice of different rasterized cylinders. Indeed, the size and the depth of the alveoli, or the engraving technique used are parameters that must be defined before making a gravure cylinder.

The engraving of the printing cylinders must be done with great care, fineness and precision to obtain a high-quality print.

THE REMOVAL OF THE COPPER

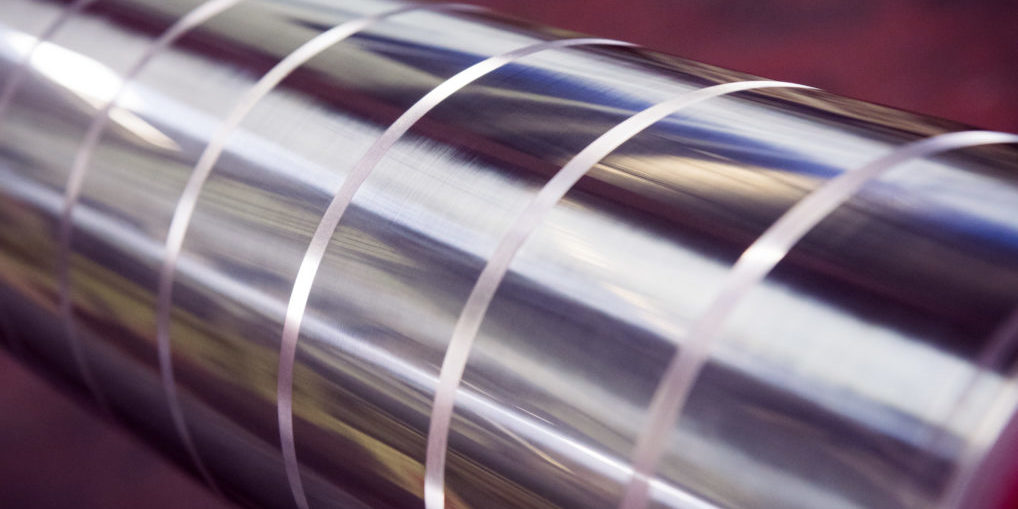

The first step, which is common to all the techniques of engraving, is the removal of a thin layer of copper on the core of the base cylinder, which is most often in steel. But today more and more of these cylinders are made in lighter materials to reduce their costs and to facilitate their handling.

Copper is deposited by electroplating. This means that a layer of metal (in this case copper) is deposited on the surface of the object with a direct electrical current. It is initially in the form of cations in solution in a solvent (usually water).

The cylinder is then systematically polished, in order to obtain the smoothest touch possible. It can also be ground or cut according to customer demand.

THE DIFFERENT TYPES OF BURNING

o Electromechanical engraving

The electromechanical engraving is one of the most used techniques in the market. A diamond stylus driven by electromechanical impulses engraves cells in the copper layer. It is the set of engraved cells that makes up the image to smear.

This technique ensures a high print quality. Indeed, depending on the size and depth of the engraved cells, we can adjust the amount of ink deposited and the print quality.

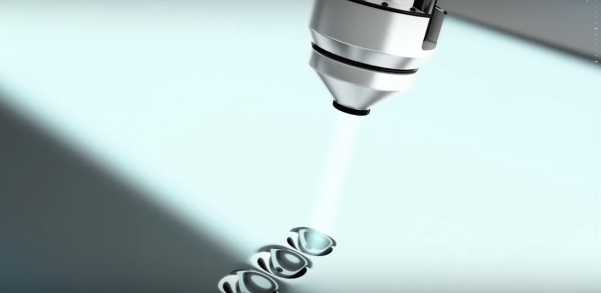

o Direct laser engraving

This technique requires you to first put a layer of zinc (by electroplating) over the copper layer. It is then a laser beam that will create the image on this outer layer.

The alveoli can be of different shapes and sizes, in order to obtain different levels of fineness. Indeed, the smaller the alveoli, the higher the fineness and the printing quality. Direct laser engraving is used for printing on aluminium.

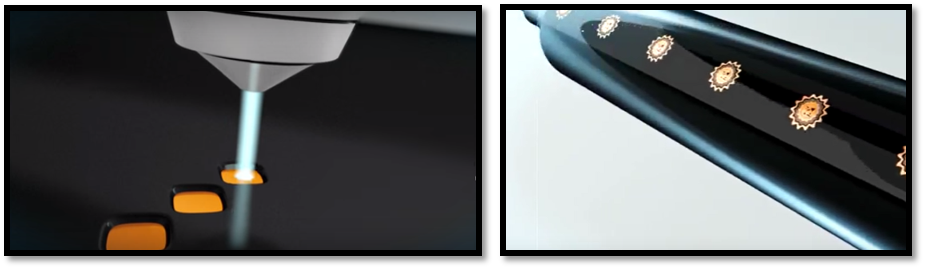

o Laser engraving and chemical attack

This technique requires a protective layer of black polymer (3-5 µm of thickness) to be applied over the copper layer. The laser beam reproduces the desired design by selectively removing the protective resin, without affecting the copper depth (it only marks the surface). A ferric chloride solution finally attacks the copper layer, where it is no longer protected by the black resin. Finally, this protective layer is removed through a final wash.

This technique is known as being the first technique of illustration used in rotogravure. This method is characterized by its very high engraving resolution and is used, for example, for printing in the area of security threads.

o Embossing

In this case, a milling head is used to burn on the surface of copper the design that the customer wants to emboss. In general, it is necessary to have two embossed cylinders (a ‘male’ and a ‘female’) when printing with this technique.

It is a print finishing technique very appreciated for its wide panel of applications, and which is very often used for packaging cardboard printing (e.g. cigarette packet).

PROTECTION BY CHROMIUM

The final stage in the preparation of the cylinders in rotogravure is chrome. As with copper and zinc, chromium is deposited by electroplating. This protects the copper layer and the engraved image against corrosion, tarnishing, wear…

Mickaël Reynier, R&D engineer