People over 40 years old will remember that when eating an individual portion of melted cheese (like La Vache qui Rit®), it was difficult not to have “sticky fingers”.

Taking this into consideration, the idea of making a system of easy opening for the individual portions of melted cheese, as well as other packaging and overpackaging food was born. In the 1970s, Rexor worked with a famous cheese factory to develop this easy opening system. This small tape of red color called Tircel® often goes unnoticed in the final product, and yet its utility is essential.

Indeed, this tear tape makes it possible both to perfectly seal the portion of melted cheese, and also to provide a very easy opening for tearing the aluminum foil which packages the cheese. Thanks to this sealing, the cheese does not oxidize and can be stored for a long time, even outside the refrigerator.

For many years, the word Tircel® has fallen into the common language of the main players in the world of packaging to define an easy opening system for cheese portion.

However, two technologies need to be differentiated.

The Tircel® created by REXOR is a heat-sealing tear tape. The Tircel® is sealed to the aluminum shell thanks to its suitable varnish with that of coated aluminum. It is opposed in terms of process to the tear tape known as PSA (Pressure Sensitive Adhesive) which can be found on the overpackaging of the cigarette pack for example and which sticks by simple pressure.

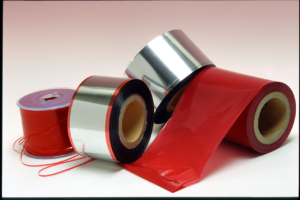

The Tircel® is most often in coils with small widths (80mm), also called pancakes.

On the other hand, The PSA hand is presented in wire (width 2mm for example).

The Tircel® is available in a wide and varied range to meet different technical requirements. It exists in polyester, polypropylene, metallised, transparent bases, with or without red bands (but which can also be blue, green, white …). The main version of the Tircel® is a metallised or non-metallised plastic film, varnished on one or two sides and printed or with colour strips, usually red. The other version is in the form of a complex, i.e., two plastic films laminated to each other.

A multitude of references exists to be able to adapt to all the sizes of portions that exist on the market (the most common being the triangular portion of 17g). There are also different shapes (square, cubic, triangular), with each time technical constraints to raise (sealing, folding, ease of cutting).

As mentioned earlier, this Tircel® must be suitable for all types of packaging machines. Thus, the presentation of the reels takes place in different widths, with one or two red strips or other colours, on mandrels of different diameters, with lengths of coils of varying length. The direction of winding is also important because the properties of the varnishes vary from one face to the other (sealing temperature or metallisation for example).

REXOR has been manufacturing the Tircel® for over 40 years, which operates in all cheese portion packaging machines.. About 140 million cheese portions are produced with Tircel® every year worldwide!

Laurence Touillon, BU Food Manager