One of the major trends for luxury brands is to offer their products with better eco-designed packaging. They insist on this point in their annual reports, putting environmental considerations at the heart of their strategic thinking.

They therefore expect their suppliers to be able to propose solutions in order to minimise the environmental impact of their packaging. One of the special features of luxury packaging is the fact that while the notions of recycling, compostability are important, the solution should not call into question the ” Luxurious appearance of the packaging”.

Since luxury is defined by what is refined and sumptuous, a packaging that would send an opposite message would risk confusing the overall impression the brand is trying to convey. With this in mind, we will observe the examples here below from the angles of “environmental benefit level” and “luxurious aspect”. Luxurious aspect being the level of glossiness.

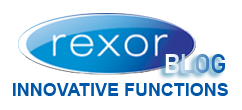

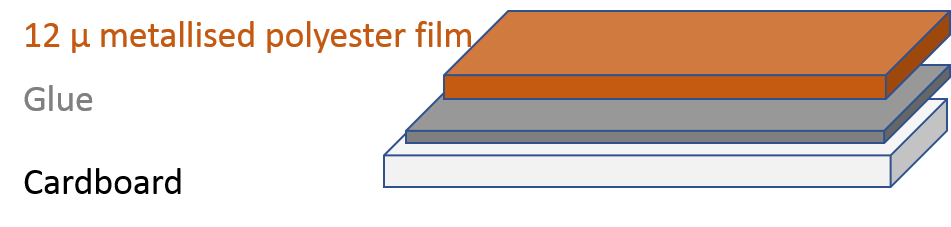

To be able to compare the solutions, we will take the most used structures in the luxury packaging sector. It is a cardboard laminated with a printable metallized polyester.

TO REDUCE POLYESTER FILM THICKNESS

Instead of using a 12 microns’ polyester film, it is possible to use a polyester film of 10; 8 or even 6 microns! The advantage of this solution is that it is possible to measure immediately the gain on the environmental impact. In the case of 6 microns, half the polyester is used: less energy required to manufacture it, the packaging is lighter and the manufacturing process is not changed: we remain on a cardboard laminated with a metallised polyester.

Some points need to be improved with this solution. The thinner the film, the harder it is to work: it breaks more easily and is more sensitive to folds and creases. Finally, the films of lower thickness present on the market do not meet for the moment the criteria of brilliance required by luxury packaging. It should also be noted that the thinner films have a higher cost per square meter.

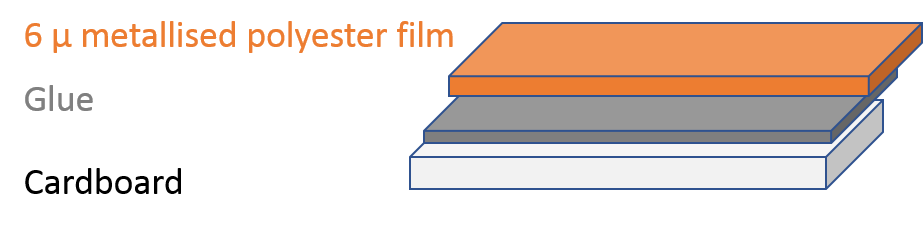

TO USE A BIO-SOURCED PLASTIC FILM RATHER THAN POLYESTER

In this case, the plastic film laminated on the cardboard will come from a renewable source, such as corn. This makes it possible to get rid of raw material from fossil resources. Moreover, the complex becomes compostable because the PLA degrades naturally over time.

This solution also has some limitations: first the PLA presents an ecological balance (as evaluated by the ADEME taking into account criteria such as acidification, eutrophication … in total 8 criteria) worse than the polyester. The water consumption necessary for its manufacture classified it as the least ecological solution for this application. Another downpoint comes from the fragility of this type of film: its mechanical characteristics are indeed much less than the polyester.

TO USE A TRANSFER METALLISED BOARD

It is a cardboard that is metallized and printable without any plastic film. It is today the best solution to meet the double requirement of brightness and ecodesign. The level of gloss meets the expectations of luxury standards and the absence of polyester film offers brands the possibility of having a lighter and environmentally friendly packaging.

The point of vigilance on this product comes from its brittleness to be scratched, as there is no longer polyester film to protect the metallization. The printer must therefore be careful when using this metallized cardboard.

As we have seen, there are three major families to make eco-friendly packaging more eco-responsible. Each solution has advantages and disadvantages. Rexor believes that the cardboard transfer metallic solution is the one with the most future in the particularly demanding luxury sector.

Renaud Vuillet, Marketing manager